PVD Design/Process Considerations

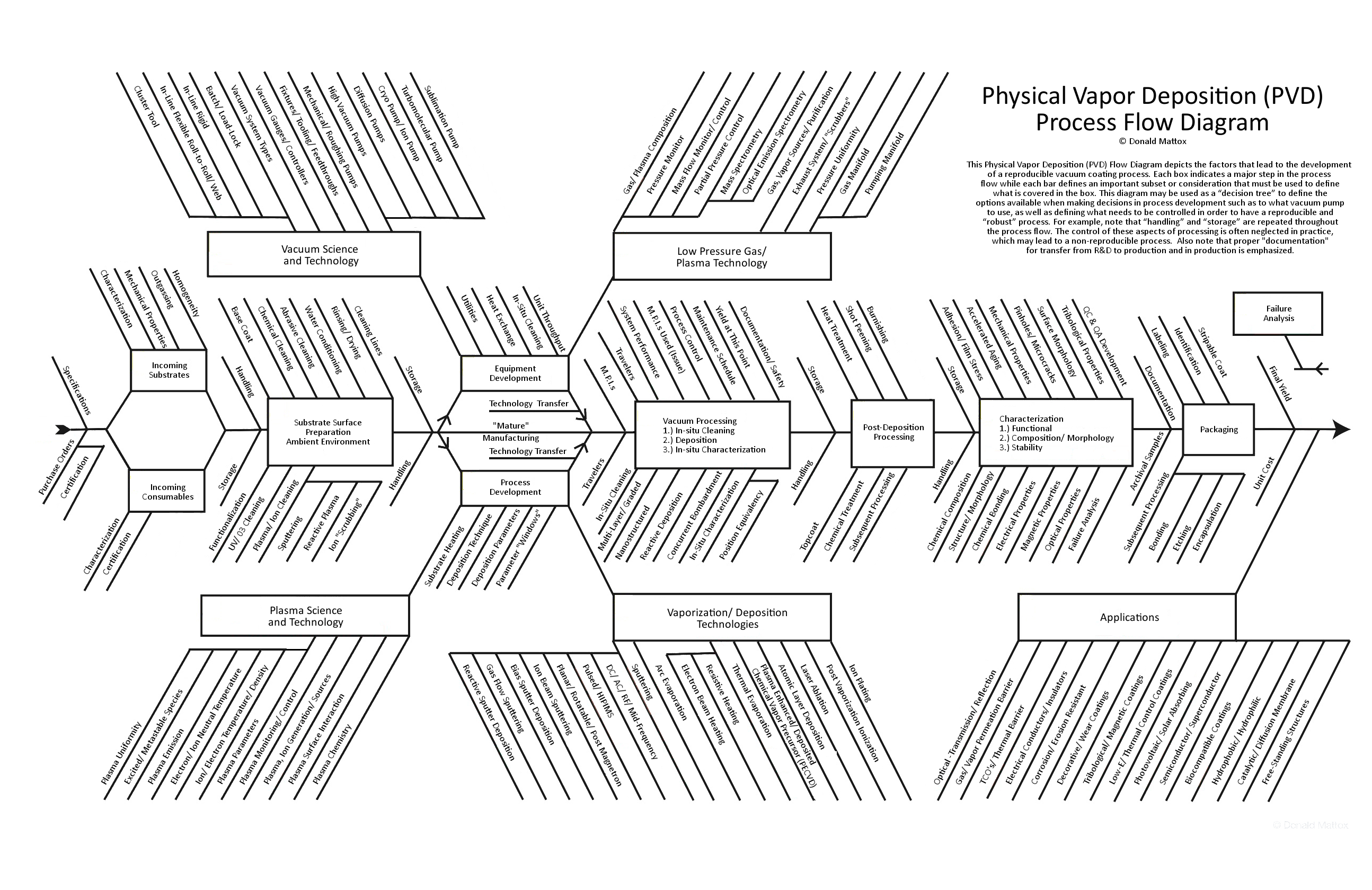

The PVD Process Flow Diagram shows the major stages of the processing along the horizontal axis as well as the decisions to be made in developing the equipment, processing and processing parameters to achieve a high-yield reproducible process.

The major stages of a vacuum coating process are:

• Characterization of in-coming material • Substrate preparation and handling • Vacuum deposition system design and operation • Deposition process design and optimization of “parameter windows” • Post deposition and subsequent processing • Inspection and characterization • Failure analysis • Handling and packaging • Post service failure analysis

Click on Flow Diagram to open full size.

Visit the Blog page to learn more about the Process Flow Diagram and other Blog Posts.